EPS F350

Product Info

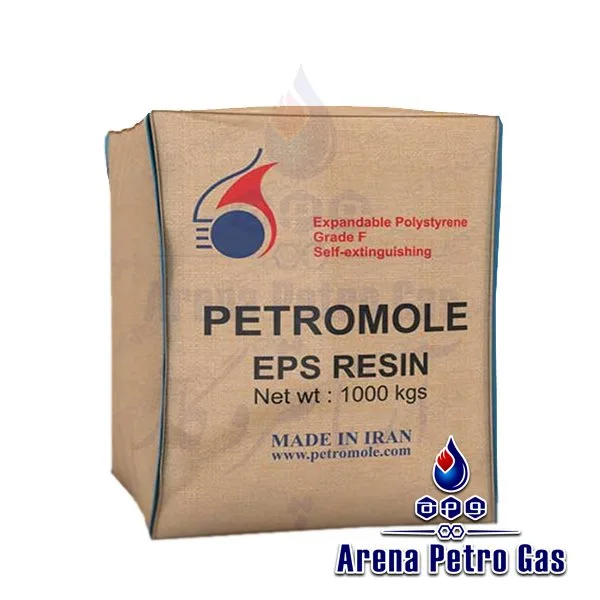

EPS F350 is an expandable polystyrene (EPS) and Arena Petro Gas is in position to supply and export it directly from PETROMOLE through its trading services according to the following specification and technical properties.

In addition, It is a polymer that can increase its volume when exposed to heat, due to the presence of a hydrocarbon agent such as pentane within its structure. EPS F350 is a fire-retardant grade of EPS that has a foam density of 35 kg/m3 and a water absorption rate of 0.5%.

EPS F350 has many applications in various industries, such as:

- Construction: insulation material for walls, roofs, floors and pipes, and a lightweight filler for concrete blocks and panels.

- Packaging: EPS F350 can be used as a cushioning material for transporting fragile and shock-sensitive goods, such as electronics, appliances, furniture and food.

- Industrial and domestic equipment: making refrigerators, freezers, air conditioners, heaters and water heaters.

- Decoration: a material for making sculptures, models, signs, ornaments and other decorative items.

The technical specifications of EPS F350 in PETROMOLE are:

- Chemical formula: C8H8

- Molecular weight: 104 g/mol

- Melting point: 240°C

- Glass transition temperature: 100°C

- Pentane content: 5-7%

- Particle size: 0.4-2 mm

- Expansion ratio: 40-60 times

- Compressive strength: 150 kPa

- Thermal conductivity: 0.035 W/mK

- Flammability rating: UL94 V0

Finally, if you are looking for EPS F350 from PETROMOLE plants, Arena Petro Gas company is ready to supply you as its trading services according to your requirements and in accordance to the manufacturers' specifications, you can easily submit your order online.

Expanded Polystyrene EPS F350

EPS F350 refers to a specific grade of expanded polystyrene (EPS). EPS, also known as styrofoam, is a lightweight plastic foam widely used in various industries. The "F350" designation indicates a particular set of physical properties for this EPS material. These characteristics can vary depending on the manufacturer, but typically F350 EPS offers the highest density and compressive strength among the commonly mentioned F grades (F150, F200).Key characteristics of EPS F350 may include:

- Density: EPS F350 might have a specific density range, such as 2.5 to 3.0 kg/m³. This high density makes it the most robust variety among F150, F200, and F350.

- Compressive Strength: F350 EPS likely possesses the highest compressive strength value compared to lower F grades, enabling it to withstand significant loads without collapsing.

- Limited Thermal Insulation: Due to its higher density, EPS F350's thermal insulation properties might be slightly lower compared to lower density EPS grades. However, it can still offer some level of insulation.

Applications of EPS F350

The exceptional strength and density of EPS F350 make it suitable for specialized applications requiring superior load-bearing capabilities:- Construction:

- Building foundations: EPS F350 blocks can be used in specific foundation applications to distribute weight and create a stable base, depending on engineering specifications.

- Load-bearing walls: Certain EPS F350 variations, combined with proper reinforcement techniques, might be suitable for specific non-load-bearing or low load-bearing wall applications. It's crucial to consult with structural engineers for appropriate usage.

- Roofing with extreme load requirements: EPS F350 can handle heavier loads on roofs compared to lower density EPS grades, making it suitable for applications with heavy roofing materials or extreme weather conditions.

- Industrial Applications:

- Heavy machinery and equipment packaging: The high density of EPS F350 provides exceptional protection for very heavy machinery and equipment during transportation and storage.

- Buoyancy applications: While not as lightweight as lower density EPS grades, F350 variations might find use in specific buoyancy applications where some structural support is also required, depending on the design.

- Cold storage construction: EPS F350's structural strength, combined with its remaining thermal insulation properties, might be suitable for specific cold storage construction elements.

Countries Producing and Using EPS F350

Production: While information on specific countries solely producing EPS F350 is limited, the major EPS producers mentioned earlier likely have the capability to manufacture this grade:- China

- Iran

- Germany

- South Korea

- Japan

Usage:

Countries with significant construction or industrial sectors are more likely to utilize EPS F350. This could include the aforementioned producer nations, along with:- Western European countries with advanced construction practices.

- Developing nations experiencing rapid infrastructure development.

EPS F350 Manufacturers in Iran

Iran has several manufacturers that produce high-quality EPS F350. Some of the leading manufacturers include:- Baniar Polymer: Baniar Polymer is the first and largest manufacturer of flame-retardant expandable polystyrene (EPS) in Iran. With an annual capacity of 240,000 tonnes, the company serves domestic, CIS, Middle Eastern, and European markets. Baniar Polymer produces three different grades of EPS, including non-HBCD flame-retardant EPS, regular high expansion EPS, and standard expansion and FR EPS.

- Sahand EPS Co: Sahand EPS Co, operating under the brand name Petromole, is one of the largest manufacturers of flame-retardant EPS in the Middle East. Established in 2014, the company has a production capacity of 60,000 tonnes per year, which was later expanded to 120,000 tonnes per year. Sahand EPS Co focuses on producing high-quality EPS for packaging, lightweight construction, and industrial applications.

EPS F350 Trading Supplier

Several companies in Iran are involved in the trading and supply of EPS F350. Some of the key trading suppliers include: Arena Petro Gas: Arena Petro Gas is a leading trading company that supplies and exports EPS F350 directly from PETROMOLE. The company offers a wide range of EPS products with various specifications and technical properties to meet the needs of different industries.Future Predictions and Forecasts for EPS F350

The future of EPS F350 is likely to be intertwined with the overall EPS market trends and advancements in EPS technology. Here's a closer look at some potential factors that could influence its future: Growth Drivers:- Rising Demand in Construction: The increasing focus on sustainable and energy-efficient construction practices could drive demand for high-performance building materials. EPS F350, with its potential for specific load-bearing applications and some level of thermal insulation, might benefit from this trend.

- Infrastructure Development: Developing countries experiencing rapid infrastructure growth might require robust and cost-effective building materials. EPS F350, depending on the specific application and local regulations, could be a consideration in such scenarios.

- Advancements in EPS Technology: Innovations in EPS production methods could lead to the development of F350 variations with improved properties like higher strength-to-weight ratio or enhanced thermal insulation despite the higher density. This could broaden its application potential.

Challenges and Considerations:

- Environmental Concerns: Traditional EPS production methods raise environmental concerns. The development of sustainable and biodegradable alternatives for high-density EPS grades will be crucial for long-term market acceptance.

- Fluctuating Oil Prices: EPS is a petroleum-based product, so its price can be affected by oil price fluctuations. This can impact the economic viability of EPS F350 compared to other materials.

- Stringent Regulations: Building codes and regulations regarding EPS usage might become stricter in some regions, focusing on fire safety or environmental impact. Manufacturers will need to adapt their EPS F350 formulations to comply with such regulations.